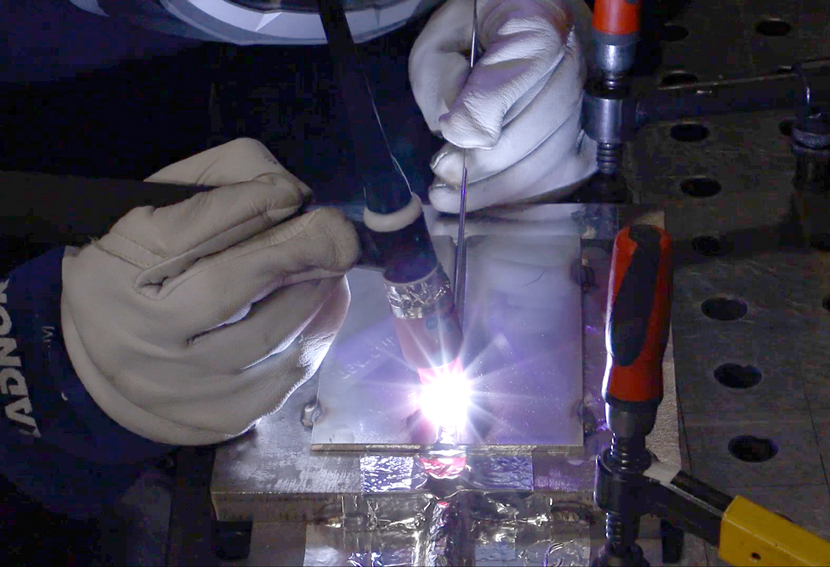

Handheld Laser Welding and Cleaning Systems

Easy to Learn & Operate • Simple & Fast to Set Up • Consistent High-Quality Results

LightWELD Unbeatable Benefits

FAST: Up to 4X faster than TIG

VERSATILE: Wide range of materials – up to 1/4 in. (6.35 mm)

EASY: Optimized presets reduce learning curve

CONSISTENT: High-quality, repeatable results

FLEXIBLE: Simple and challenging applications

PRODUCTIVE: Pre- and post-weld cleaning capability

Learn More - Download LightWELD Brochure

Adjustable laser welding power up to 1500 W Preset & user-defined modes optimize material-thickness combinations Wobble welding controls for 5 mm of additional weld width Rear panel provides intuitive connections for power, process gas and external accessory controls Cleaning power up to 2500 W peak for greater welding quality and finishing capabilit Watch Paul Sableski from Weld.com demonstrate the features, capabilities and just how easy LightWELD XC is to set up and operate at “lightning speed.” Paul uses LightWELD XC to quickly create:: 3 mm Aluminum Butt Weld Stainless Steel T-Joint, 6 mm to 1 mm Stainless Steel Lap Joint with wire feeder Speed TIG welding is a time-consuming, two-handed welding method that requires an experienced, highly-skilled operator. TIG welding may generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses. MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.LightWELD - Turnkey Handheld Laser Welding & Cleaning Systems

LightWELD - Less Heat & Distortion for More Productivity & Flexibility

Traditional Welding Methods LightWELD Laser Welding & Cleaning Average Up to 4X Faster than TIG Quality Depends on user experience Consistent high-quality results Learning Curve Steep Quick and easy Material Flexibility Limited with consumables changes Wide range with no set up Distortion & Deformation High Very Low Heat Affected Zone Large Small Wobble Welding No Yes - up to 5 mm additional weld width Pre- and Post Weld Cleaning No Yes - up to 15 mm cleaning path

ch

ch English

English